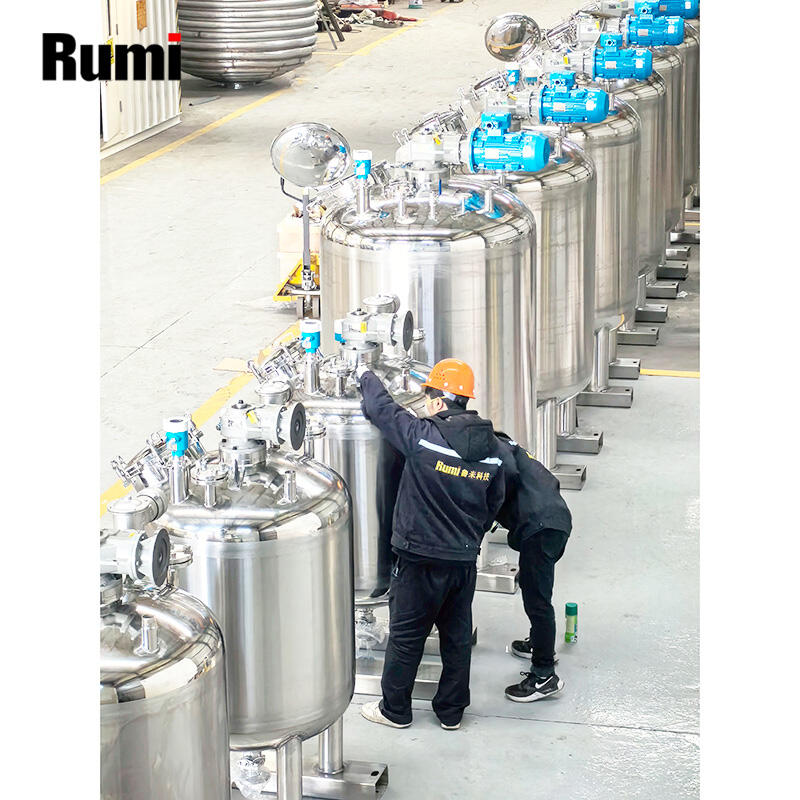

Stainless Steel Mixing Tanks with Agitator the Perfect Solution for Your Production Needs.

Are you looking for a mixing tank that is durable, safe, and easy to use? Consider a stainless-steel mixing tank with agitator. These Rumi stainless steel mixing tank with agitator are designed to meet the needs of variety of industries, from food and beverage to pharmaceuticals and cosmetics.

One of the primary advantages of stainless-steel mixing tanks is their durability. The Rumi stainless steel tank with agitator are built to withstand the harsh conditions of production environments, such as high temperatures, corrosive chemicals, and heavy use. Additionally, they are resistant to rust and other types of corrosion, which ensures a long lifespan.

Another significant advantage of stainless-steel mixing tanks is their versatility. They can be used for a wide range of applications, from mixing liquids to blending powders. They are also easy to clean and can be sanitized quickly.

Recent innovations in stainless steel mixing tanks with agitator have improved their efficiency and functionality. For example, some tanks are equipped with advanced controls that allow for precise mixing and blending of ingredients.

Other advancements of the Rumi stainless steel mixing tanks include the incorporation of heating and cooling systems that regulate the temperature of the mixing tank. This is important for certain applications where precise temperature control is necessary.

Safety is a top priority in any production environment, and stainless-steel mixing tanks with agitator are no exception. These Rumi jacketed mixing tank with agitator are constructed with safety features that protect workers and the products being produced.

For example, many mixing tanks have built-in safeguards that prevent overloading or overheating. Additionally, they may have locking mechanisms that prevent accidental spills or contamination.

Using a stainless-steel mixing tank with agitator is a straightforward process. First, the Rumi liquid mixing tank with agitator must be thoroughly cleaned and sanitized to ensure the purity of the products being mixed.

Then, the ingredients are added to the tank, either manually or through an automated system. The agitator is then activated, and the ingredients are mixed until the desired consistency is achieved.

reasonable scientific design mixing paddle, variety combinations designs provide users variety choices mixing well shearing ( stainless steel mixing tank with agitator) well homogenization (emulsification) grinding.

RUMI certified ISO9001, CE other certifications CE, ISO9001 other. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, stainless steel mixing tank with agitator Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. It's classified ""National High-Tech Enterprise" "Specialized Professional Enterprise"

primary products RUMI dispersing equipment (stainless steel mixing tank with agitator machines) grinding machines (emulsifiers), reactors tanks along high-precision metering, batching, weigh systems liquids well solids.

Training technical support high-end level provided prior sale. stainless steel mixing tank with agitator requirements users process requirements jointly create users how select sealing material, mechanical shaft seals, cooling heating methods more.