What is a 3 roll mill, and why is it important for manufacturing?

Introduction:

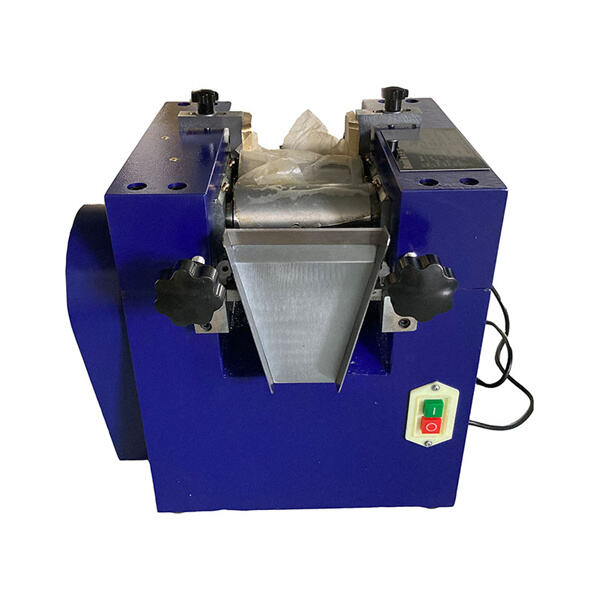

A 3 roll mill is an used machine to blend, disperse, and homogenize materials in a variety of industries, just like the Rumi's product called basket mill machine. It consists of three rollers that rotate at different speeds, which help to mix and grind the materials. The use of a 3 roll mill provides several advantages, including improved quality, faster production time, and reduced labor requirements. We will discuss the benefits of using a 3 roll mill, how it can be used safely and effectively, and the industries that benefit from this innovative technology.

A 3 roll mill provides many advantages over traditional mixing and grinding methods, along with the twin shaft disperser working built by Rumi. For example, the use of a 3 roll mill can result in a more uniform product with better dispersion. This is because the rollers apply consistent pressure to the material, which creates a more even mixture. Additionally, the 3 roll mill can help to reduce production time, as it can blend and grind materials quickly and efficiently. This can lead to improved productivity and cost savings for businesses.

Innovation in 3 roll mill technology has led to improvements in safety and efficiency, similar to the Rumi's product like three roller ointment mill. For example, newer models of 3 roll mills come equipped with safety features such as automatic shut-off switches and emergency stop buttons. These features help to prevent accidents and ensure that the machine is used safely. Additionally, advancements in automation technology have made it possible to control the 3 roll mill remotely, which can improve efficiency and reduce labor costs.

Despite the many benefits of using a 3 roll mill, it can be dangerous if not used properly, same with the high speed dispersion machine manufactured by Rumi. It is important to follow safety guidelines and wear appropriate personal protective equipment, such as gloves and safety goggles, when using the machine. Additionally, the machine should be inspected regularly to ensure that it is in good working condition and that all safety features are functioning properly.

Using a 3 roll mill is relatively simple, but it is important to follow the manufacturer's instructions carefully, also the Rumi's product such as paint bead mill. First, load the materials onto the hopper and adjust the roller gaps according to the desired size and consistency of the product. Then, turn on the machine and adjust the speed of the rollers to the appropriate level. Finally, monitor the machine closely to ensure that it is working properly and make adjustments as necessary.

RUMI ISO9001, CE, other certifications like CE, ISO9001, 3 roll mill. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, Pleantary Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. It's categorized ""National High-Tech Enterprise" "Specialized Professional Enterprise"

Expert-level 3 roll mill support or training is provided before the sale. Understand the requirements of users and requirements for the process and develop with users how to select the right sealing materials, mechanical shaft seals, cooling and heating techniques etc.

main 3 roll mill offered RUMI mixing machines, dispersing dispersing machines, grinding machines Emulsifying equipment, reactors storage tanks, ultra-precision metering batching systems powders liquids well EPC general contracting automate intelligent production lines.

reasonable scientific design mixing paddle, variety combinations designs provide users variety choices mixing well shearing ( 3 roll mill) well homogenization (emulsification) grinding.