The Homogenizer Tank: A Revolutionary Innovation in Food Processing

1. What is a homogenizer tank?

A homogenizer tank is a specialized container used in the Rumi food industry to process and store various food products. It is designed to combine and blend different ingredients into a smooth and consistent mixture, creating textures and flavors that mixing tanks are both delightful and appealing. This tank is an important tool that not only enhances the quality of food products but also ensures their safety and durability.

The use of homogenizer tanks brings numerous benefits to food processing companies. One of the primary advantages is its ability to create smooth and stable emulsions, which Rumi helps to maintain the consistency and texture of food products. Homogenized products have an uniform structure and are less likely to separate or clump, ultimately enhancing the overall quality of the food product.

In addition, homogenized products have increased shelf life, reducing food waste and mixing tank with agitator spoilage. Homogenization ensures the destruction of harmful bacteria and microorganisms, making food products safer for consumers to consume.

Homogenizer tanks are incredibly versatile and can be used to process a wide range of food products, including dairy products, sauces, salad dressing, and juices. The process of homogenization can also enhance the nutritional value of food products by breaking down and releasing important nutrients and vitamins.

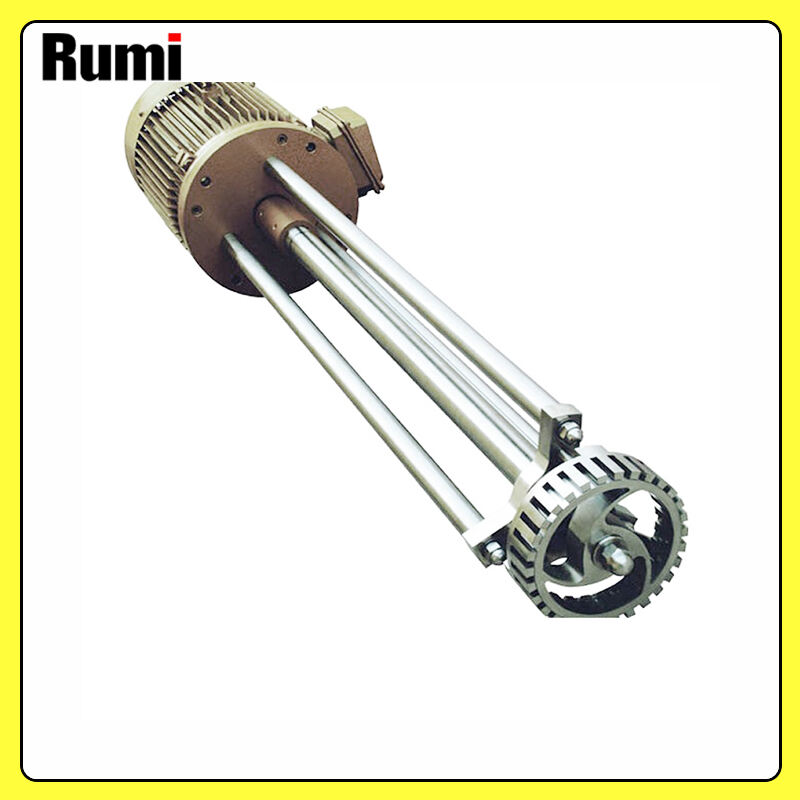

The homogenizer tank is a significant innovation in food processing technology. The Rumi design and mechanism of the homogenizer tank make it safe to use and maintain. Its advanced features include a pressure gauge and a safety valve, which regulates the tank with mixer pressure within the tank. This ensures that the tank is operating at a safe level, preventing any accidents or explosions.

Another remarkable feature of the homogenizer tank is its ability to reduce the number of harmful pathogens that may be present in food products. The homogenization process destroys the cell walls of bacteria, ensuring better food safety practices.

Using a homogenizer tank is relatively easy. First, the Rumi food products to be processed are loaded into the tank. The lid is then securely fastened and locked, and the tank is stainless steel mixing tanks pressurized with hydrogen or helium. The homogenization is then carried out according to a preset process time, temperature, and the specific needs of the product.

After the homogenization process is completed, the content is exited through the bottom outlet using a discharge valve. The tanks are then cleaned and sterilized before being used for the next batch.

Investing in a homogenizer tank from trusted manufacturers ensures that Rumi customers receive good service and quality products. Manufacturers offer installation, maintenance, and repair services that are timely and efficient, ensuring minimum disruption to the mixing tanks stainless steel production process.

Manufacturers also maintain the quality of the tanks by ensuring that they meet strict safety and hygiene standards. Tanks that have been certified by regulatory bodies are known to be reliable, durable, and of high quality.

RUMI's primary products dispersing machines, mixing machines grinding Homogenizer tank, Emulsifying equipment, reactors storage tanks, high-precision measuring batching systems liquids powders EPC general contracting automate intelligent production lines.

reasonable scientific mixing Homogenizer tank design, well range designs combinations give users wide range choices mixing well shearing (dispersion) well homogenization (emulsification) grinding.

Homogenizer tank-grade technical support or education provided prior purchase. Fully understand user needs process requirements jointly work customers select sealing materials, mechanical shaft seals, cooling heating methods etc.

RUMI Homogenizer tank ISO9001, CE other certifications, including CE, ISO9001, others. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, Pleantary Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. It's classified ""National High-Tech Enterprise" "Specialized Professional Enterprise"